Mining Ore Classifier For Froth Flotation

.jpg)

Fundamentals of froth flotation ChemTexts Springer

2022年10月18日 — Froth flotation is a physicochemical process that is used to separate fine mineral particles from aqueous suspensions by selective attachment of some types of minerals to air bubbles Froth flotation is the most important mineral processing 2024年2月1日 — Two of the most important classes of surfactants adsorbing primarily at solid–liquid interface are: (i) collectors, which increase the hydrophobicity of the mineral Frothers in flotation: A review of performance and function 2024年9月19日 — In flotation, froths are classified as either dry or wet, with “dry” and “wet” indicating the froth’s moisture content, typically measured by the liquid volume fraction φ A significant review of froth stability in mineral flotation2021年2月5日 — The sulfide ore flotation process can be studied by both chemical and electrochemical phenomena considering the interfacial energies A broad application of Froth flotation process and its application Wiley Online

.jpg)

CHAPTER9 FROTH FLOTATION AND ITS APPLICATION

2020年5月6日 — application of flotation technique to concentration of large reserves of low grade ores and fines PRINCIPLES OF FLOTATION Froth flotation utilises the 2024年3月18日 — In the mining industry, while the process of flotation plays a vital role in liberating valuable minerals from ore, achieving optimal control of froth flotation circuits is Digital twin of minerals processing operations for an 2018年3月15日 — In froth flotation, a collector (a kind of surfactant) selectively attaches to a target mineral using its minerophilic group (Somasundaran and Wang, 2006), and then New advances in the understanding and development of flotation 2022年2月23日 — One of the most widely used ore beneficiation methods is froth flotation which allows for effective processing of complex metallic ores and coal The primary goal Advanced Analytics for Mineral Processing SpringerLink

.jpg)

中国地质科学院矿产资源研究所 cgs

2023年2月7日 — 玢岩型铁矿床(铁氧化物磷灰石矿床)对成矿母岩的“选择”:来自锆石微量元素和HfO同位素的约束 安徽宁芜中生代火山盆地是中国东部最为典型的玢岩型铁矿床(铁氧化物磷灰石矿床,IOA型矿 2020年4月23日 — Froth flotation is the most widely used phosphate ore separation process Because of the nature of the phosphate ore, such as mineral types and content, disseminated particle size, its separation 5 Types of Phosphate Froth Flotation ProcessIn ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer For Froth Flotation Process Detailed Explanation 2011年1月1日 — After froth flotation, each product of froth flotation recovered (froth and depressed) were allowed to settle for 24 hours before decanting, filtered, dried at a temperature of 105 °C and weighed(PDF) Fundamental principles of froth flotation

4 types froth flotation process of fluorite ore Mining Pedia

2022年2月21日 — (4) Sulphide fluorite ore: its mineral composition is basically the same as quartzfluorite but contains more metal sulfides, sometimes lead and zinc content can reach industrial grade Froth Flotation Process of Different Types of Fluorite Ore 1 Froth Flotation of Quartz Fluorite Ore2019年11月9日 — Froth flotation method is a kind of mineral processing technology that the solid minerals emerge from water suspension (slurry) according to the physical and chemical properties of the mineral surface According to statistics, more than 60% ~ 70% ore in the world is separated by froth flotation method, involving more than one hundred kinds of Advantages and Disadvantage of Froth Flotation Method2019年3月1日 — The froth flotation process is a mineral processing technology with a wide application range and strong adaptability It can be applied to almost all kinds of minerals such as nonferrous metals, rare metals and nonmetals And it can process more than 100 minerals, especially for gold extraction3 Factors Affect Froth Flotation Process? MiningpediaFroth flotation is a physicochemical process that is used to separate fine mineral particles from aqueous suspensions by selective attachment of some types of minerals to air bubbles Froth flotation is the most important mineral processing technology for the production of valuable mineral concentrates from which metals and minerals are obtained Practically Fundamentals of froth flotation ChemTexts Springer

Bastnaesite Beneficiation by Froth Flotation and Gravity

2024年4月1日 — Rare earth elements are in high demand in the USA Bastnaesite, a rare earth fluorocarbonate containing primarily cerium and lanthanum, is one of the most abundant sources of rare earths in the USA This research was completed using the ore from Mountain Pass, which is the largest rare earth mine in the USA This research, 6 天之前 — A typical run of mine ore can contain 12% Li2O, while a typical spodumene concentrate is suitable for future lithium battery production Fine crusher / Cone crusher, Vibrating screen, Ball mill machine, Spiral classifier / Hydrocyclones, Slurry mixing tank, Chemical mixing tanks, Froth flotation cells, Thickener, Vaccum filter, Belt Lithium Ore Flotation Plant Pineer Mining Machinery2012年1月2日 — With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an Froth Flotation of Iron Ores articlesapub2019年11月1日 — Under a certain flotation conditions,there exists a suitable pH value for any kind of mineral flotation Only in this pH value, can the froth flotation process obtain the better index Therefore,controlling the pH Seven Factors Influence the Effect of the Froth

Froth Flotation Analysis of Oxidized Leadzinc Ore

2019年9月24日 — Froth flotation is a process for selectively separating hydrophobic materials from hydrophilic,which is suitable for leadzinc oreBut the flotation of oxidized leadzinc ore is a difficult one In the treatment of 2019年9月12日 — Flotation agents are agents used in the mineral flotation process that can adjust the surface properties of minerals and increase or decrease mineral floatability,which makes ore pulp properties and foam How Collector Usage Affect Froth Flotation 2018年2月6日 — Pre19th century placer mining operations used mercury to dissolve the gold in crushed ore, making it easier to recover Later innovations include the MacArthurForrest Process and borax flux extraction However, one of the most interesting methods is froth flotation Froth flotation works by exploiting the hydrophobic properties of gold moleculesRecovering Gold through the Froth Flotation Process2018年12月20日 — 6 Interaction of pulp density, flotation conditions and ore properties The most suitable ore pulp concentration during the flotation process is related to the ore property and the flotation processing conditions The general rules as flow: (1) Pulp Density The mineral with large flotation density uses a thicker slurry, while the mineral with 7 Factors Affecting Froth Flotation Process JXSC Machine

.jpg)

Advanced Analytics for Mineral Processing SpringerLink

2022年2月23日 — One of the most widely used ore beneficiation methods is froth flotation which allows for effective processing of complex metallic ores and coal The primary goal during coal processing involves reducing the ash and sulfur content, whereas during metallic ore processing, it includes the separation of metals like copper, lead, and zinc from the 2020年2月26日 — Classifier; Vibrating Screen; Magnetic Separator; Here are 5 commonly used froth flotation methods for PbZn sulfide ore extraction: Priority froth flotation method But for the complexity of leadzinc ore, it is suggested that each mine owner should adopt the scientific and reasonable froth flotation method according to the report of How to Select the Froth Flotation Method Used in the Mining Flotation, in mineral processing, method used to separate and concentrate ores by altering their surfaces to a hydrophobic or hydrophilic condition—that is, the surfaces are either repelled or attracted by water The flotation process was developed on a commercial scale early in the 20th century toFlotation Mineral Processing, Separation Beneficiation2024年2月1日 — The flotation process is a separation technique primarily used in mineral processing for the recovery of minerals (Wills and Finch, 2016), that also finds application in other industrial processes such as wastewater treatment and paper recycling (Saththasivam et al, 2016, Vashisth et al, 2011)Separation of mineral particles by flotation takes Frothers in flotation: A review of performance and function

.jpg)

How Froth Flotation Works 911Metallurgist

2015年8月8日 — To start with I will give you a simplified description of how selective froth flotation works, lets start over again with a description of the equipment and why it works When the grinding circuit is finished with the ore it will be ground very fine and the density of the slurry will be between 30% to 45% solids2021年8月1日 — We collected flotation froth images of leadzinc [46], nickel ore and uses YOLOv5 based deep learning framework to tackle the problem of data mining of flotation froth It provides realtime Froth image feature engineeringbased prediction method for 2022年2月21日 — (4) Sulphide fluorite ore: its mineral composition is basically the same as quartzfluorite but contains more metal sulfides, sometimes lead and zinc content can reach industrial grade Froth Flotation Process of Different Types of Fluorite Ore 1 Froth Flotation of Quartz Fluorite Ore4 types froth flotation process of fluorite ore Mining PediaFroth flotation is the use of the physical and chemical properties of the surface of the ore, the use of chemical separation of useful ore In the process of froth flotation, useful minerals are separated by floating them in the foams, and the way of keeping gangue minerals in the pulp is called positive flotation, while the way of floating Mineral Flotation, Flotation Separation, Forth Flotation

7 Common Problems and solutions of Froth Flotation Method

2019年12月13日 — For example, a copper and cobalt oxide mine in Congo,the main copper content is malachite, and the cobalt mineral is hydrocobalt In order to improve the froth flotation method effect, the sodium thiohydride and ammonia sulfide was used to improve the effect of froth flotation method in a 1:1 ratio 22019年2月25日 — Froth Flotation At the beginning of the 20th century, the primitive froth flotation method appeared, which separates minerals according to the difference in physicochemical properties of the ore surface At present, froth flotation process has become the most widely used ,and the process has developed relatively mature The Development of Froth Flotation miningpedia2024年9月7日 — Small Scale Lead Ore Gold Mining Mine Froth Flotation Machine for Sale US$2,00000 / set: 1 set (MOQ) Product Details Customization: Available: Type: Flotation Separator: Voltage: 220V/380V spiral classifier JIg machine shaking table Flotation Separator View all Drying and calcining equipment Dehydration filtration machineSmall Scale Lead Ore Gold Mining Mine Froth Flotation 2024年3月24日 — Flotation stands out as a successful and extensively employed method for separating valuable mineral particles from waste rock The efficiency of this process is subjected to the distinct physicochemical attributes exhibited by various minerals However, the complex combination of multiple subprocesses within flotation presents challenges Advancements in Machine Learning for Optimal Performance in Flotation

Digital twin of minerals processing operations for an

2024年3月18日 — The froth flotation process typically involves a series of multiple flotation cells arranged in a sequential manner This configuration allows for a stepwise separation of valuable minerals from the ore, with each cell playing a specific role in the overall process []The use of multiple cells in series enhances the efficiency of the flotation process by graphite ore Özcan Öney1,a, and Selçuk Samanli1 1Usak University, Department of Mining Engineering, 64200 Usak, Turkey Abstract In this study, the enrichment of the Kütahya Altıntas graphite ore by flotation was carried out Flotation parameters such as particle size, pH, type and dosage of collector, andDetermination of optimal flotation conditions of low 2016年10月18日 — The ores from which silver and gold are recoverable by flotation divide themselves naturally into two general processing classes: Thus, in a leadzinc ore, silver is more valuable in the lead than in the zinc concentrate circuit In the first cell of each machine, sometimes in the first two cells, a finished concentrate is made The Silver Gold Recovery Flotation Process 911Metallurgist2021年11月1日 — Froth flotation is a physicochemical separation technique that exploits the difference in the surface wettability of mineral particles (Wills and Finch, 2016)From a heterogeneous mixture of solids, hydrophobic particles are made to attach to gas bubbles and subsequently carried to the froth phase and recovered as a froth product (typically Hydrodynamics of froth flotation and its effects on fine and

.jpg)

How to Process LowGrade Lead Zinc Ore by

2016年4月27日 — A thorough washing and some disintegration is given the ore by the trommel screen The minus 2″ material passes to a cone or Forced Feed Jaw Crusher and is reduced to approximately minus ½” A 2024年9月3日 — EMJ explains how a holistic approach to the optimization of flotation, encompassing equipment, technology and knowhow can deliver circuits fit for the mining operations of tomorrow By Carly Leonida, Froth Flotation for the 21st Century E MJSeparation of plastic wastes using froth flotation – An overview Ozan KökkılıçShiva MohammadiJamPengbo ChuChristopher MarionYing YangKristian E Waters, in Advances in Colloid and Interface Science, 2022 5 Froth flotation Froth flotation is a physicochemical separation process based on the differences in surface properties of materials This Froth Flotation an overview ScienceDirect Topics2022年1月6日 — Lowcost and environmentfriendly green froth flotation modifiers of plant origin, such as guar gum, carboxymethyl cellulose (CMC), and starch, have been used in flotation of some sulfide and nonsulfide minerals Certain green modifiers may be used as dispersants, flocculants, depressants, or activators The functions of green modifiers in Fundamentals and Applications of Green Modifiers for Froth Flotation

How to Choose the Froth Flotation Process According to Mining

2019年11月6日 — One One stage froth flotation One stage froth flotation is the froth flotation process after a primary grinding (the ore is ground to the upper limit of particle size that can float), and any flotation products do not need to regrinding, that is called one stage froth flotation process, or one stage grindingfroth flotation process 2020年5月26日 — Froth flotation process as a complex physical and chemical beneficiation process, flotation stage has a great impact on the phosphate beneficiation index, and the effect of this stage will directly affect the subsequent processesIn order to ensure that phosphate ore flotation get a higher process index, the key to obtain a better technical 7 Factors Affecting Phosphate Froth Flotation Miningpedia2016年5月7日 — A frother such as pine oil is usually added for froth control Potash Flotation The conditioner and reagentized saltbrine slurry is floated in a “SubA” Flotation Machine In the circuit shown, roughing is accomplished in a “SubA” Free Flow Flotation Machine with no intermediate weirs or feed pipesPotash Flotation Process 911MetallurgistThis thorough volume describes stateoftheart research and practice in mineral froth flotation as known and practiced a century after its introduction Recognized experts provide indepth coverage on the historical aspects of flotation; flotation fundamentals; flotation chemistry; flotation cells, modeling, and simulation; and flotation plant practiceFroth Froth Flotation: A Century of Innovation Google Books

.jpg)

Common Questions About Froth Flotation Process Technology Mining

Froth flotation is the use of the physical and chemical properties of the surface of the ore, the use of chemical separation of useful ore In the process of froth flotation, useful minerals are separated by floating them in the foams, and the way of keeping gangue minerals in the pulp is called positive flotation, while the way of floating gangue minerals in the foam is called 2020年4月23日 — Froth flotation is the most widely used phosphate ore separation process Because of the nature of the phosphate ore, such as mineral types and content, disseminated particle size, its separation 5 Types of Phosphate Froth Flotation ProcessIn ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layer For Froth Flotation Process Detailed Explanation 2011年1月1日 — After froth flotation, each product of froth flotation recovered (froth and depressed) were allowed to settle for 24 hours before decanting, filtered, dried at a temperature of 105 °C and weighed(PDF) Fundamental principles of froth flotation

4 types froth flotation process of fluorite ore Mining Pedia

2022年2月21日 — (4) Sulphide fluorite ore: its mineral composition is basically the same as quartzfluorite but contains more metal sulfides, sometimes lead and zinc content can reach industrial grade Froth Flotation Process of Different Types of Fluorite Ore 1 Froth Flotation of Quartz Fluorite Ore2019年11月9日 — Froth flotation method is a kind of mineral processing technology that the solid minerals emerge from water suspension (slurry) according to the physical and chemical properties of the mineral surface According to statistics, more than 60% ~ 70% ore in the world is separated by froth flotation method, involving more than one hundred kinds of Advantages and Disadvantage of Froth Flotation Method2019年3月1日 — The froth flotation process is a mineral processing technology with a wide application range and strong adaptability It can be applied to almost all kinds of minerals such as nonferrous metals, rare metals and nonmetals And it can process more than 100 minerals, especially for gold extraction3 Factors Affect Froth Flotation Process? MiningpediaFroth flotation is a physicochemical process that is used to separate fine mineral particles from aqueous suspensions by selective attachment of some types of minerals to air bubbles Froth flotation is the most important mineral processing technology for the production of valuable mineral concentrates from which metals and minerals are obtained Practically Fundamentals of froth flotation ChemTexts Springer

.jpg)

Bastnaesite Beneficiation by Froth Flotation and Gravity

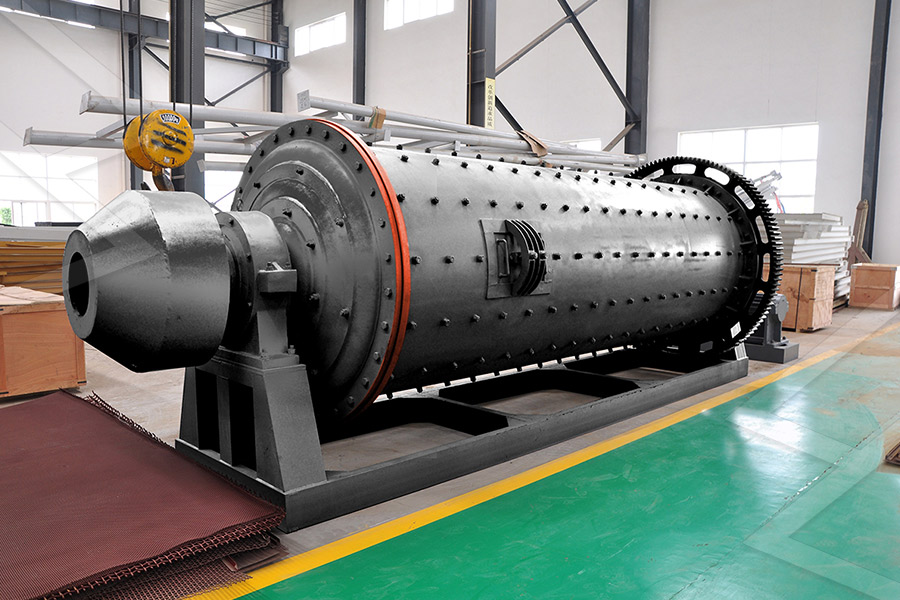

2024年4月1日 — Rare earth elements are in high demand in the USA Bastnaesite, a rare earth fluorocarbonate containing primarily cerium and lanthanum, is one of the most abundant sources of rare earths in the USA This research was completed using the ore from Mountain Pass, which is the largest rare earth mine in the USA This research, 6 天之前 — A typical run of mine ore can contain 12% Li2O, while a typical spodumene concentrate is suitable for future lithium battery production Fine crusher / Cone crusher, Vibrating screen, Ball mill machine, Spiral classifier / Hydrocyclones, Slurry mixing tank, Chemical mixing tanks, Froth flotation cells, Thickener, Vaccum filter, Belt Lithium Ore Flotation Plant Pineer Mining Machinery2012年1月2日 — With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an Froth Flotation of Iron Ores articlesapub