Argentina Iron Ore Grinder Mill

Argentina: Mining, Minerals and Fuel Resources

The important mineral resources present in the country include lead, zinc, tin, copper, iron ore, manganese, petroleum, uranium, and lithium In 2016, the mining sector contributed $178 billion to Argentina’s GDP, 2015年7月28日 — Argentina s sole iron ore producer MCC Sierra Grande expects to recover full operations by the end of the year, when it plans to bring water supplies back to Argentina's MCC Sierra Grande iron miner expects full 2022年3月19日 — An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific Grinding iron ore concentrate by using HPGR and ball mills 2022年8月25日 — 由FMG公司生产的品位575%左右的火箭粉,硅5个左右,铝2个左右,其它冶炼性能同火箭粉。 超特粉的品位低于火箭特粉1个品位,在565%左右,硅6左右,铝3个左右,结晶水在85%左右,其它冶炼 全梳理!一文了解铁矿石种类、全球分布、世界著名

.jpg)

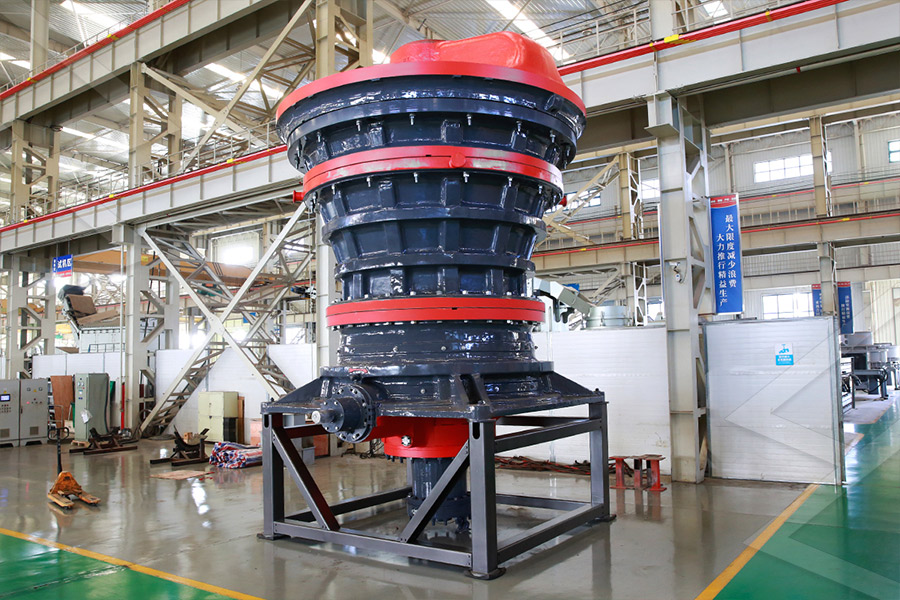

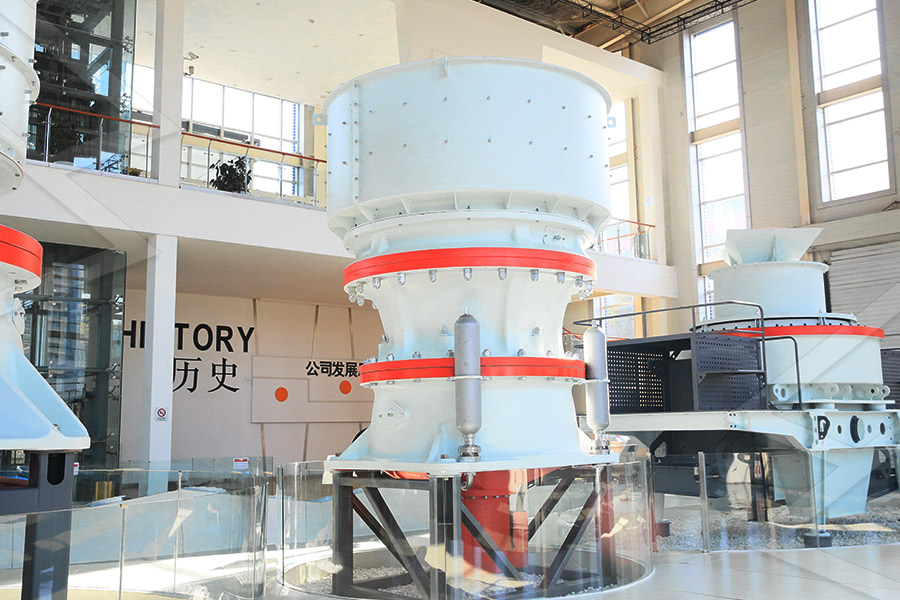

Processing Materials Ultrafine Powder

ultrafine powder mills main include HGM series ultrafine grinding mills and CLUM series vertical roller mills They can process hundreds of ore materials, grind hard stone into fine powder ultrafine grinder is the 2015年3月15日 — The application of vertical roller mills (VRMs) for ore grinding is a part of the strategies against rising energy consumption (Reichert et al, 2015) Schematic Research of iron ore grinding in a verticalrollermill2024年9月6日 — Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive Research of iron ore grinding in a verticalrollermill2023年9月3日 — Of the five materials tested in a large pebble mill grinding quartzitic ore, AMS grids and white iron blocks performed best on a costlife basis, with possibly argentina iron ore grinding mill Sabo Mining Machinery

.jpg)

Development of a Novel Grinding Process to Iron Ore

2020年5月15日 — Modern iron ore pelletizing process operations may be divided into two main process sections: feedstock preparation and agglomeration processes In most Grinding The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or screening after milling, which decreases the kWhr per ton ground When the material exits the mill, the iron ore is classified using The six main steps of iron ore processing Multotec2024年4月26日 — Grinding Mills: Grinding mills, such as ball mills and rod mills, are commonly used for grinding iron ore These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into smaller particles The choice of grinding mill depends on factors such as the desired product size, capacity requirements Iron Ore Processing: From Extraction to Manufacturing2020年10月18日 — An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesThe effects of iron ore concentrate grinding methods (HPGR

.jpg)

Mechanistic modeling and simulation of grinding iron ore

DOI: 101016/JPOWTEC202107030 Corpus ID: ; Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills @article{Carvalho2021MechanisticMA, title={Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills}, author={Rodrigo M de You need IronMills Professional kitchenware that you can trust! FREE SHIPPING, UK MADE, 10 YEAR WARRANTY Argentina GBP £ IronMills Grinders will Amaze Your Senses Our luxury castiron salt and pepper mills are a treat for all your senses Each mill is carefully cast and finished IronMills Quality Cast Iron Salt Pepper Mills UK Made2024年1月2日 — Population balance model approach to ball mill optimization in iron ore grinding Patricia M C Faria1,2, Luís Marcelo Tavares2 and Raj K Rajamani3 1 Vale SA, Brazil 2 Department of Population balance model approach to ball mill 2020年3月28日 — Based on batch grinding method and normalization idea, a conical ball mill is used and a quantitative separation method of grinding characteristics of multicomponent complex ore is proposedDevelopment of a Novel Grinding Process to Iron Ore

.jpg)

Research of iron ore grinding in a verticalrollermill

Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGate2015年3月15日 — Pilot scale mill LM45 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 2 Various Research of iron ore grinding in a verticalrollermill2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the A Review of the Grinding Media in Ball Mills for Mineral 2012年6月1日 — PDF The paper presents an overview of the current methodology and practice in modeling and control of the grinding process in industrial ball mills Find, read and cite all the research you (PDF) Grinding in Ball Mills: Modeling and Process Control

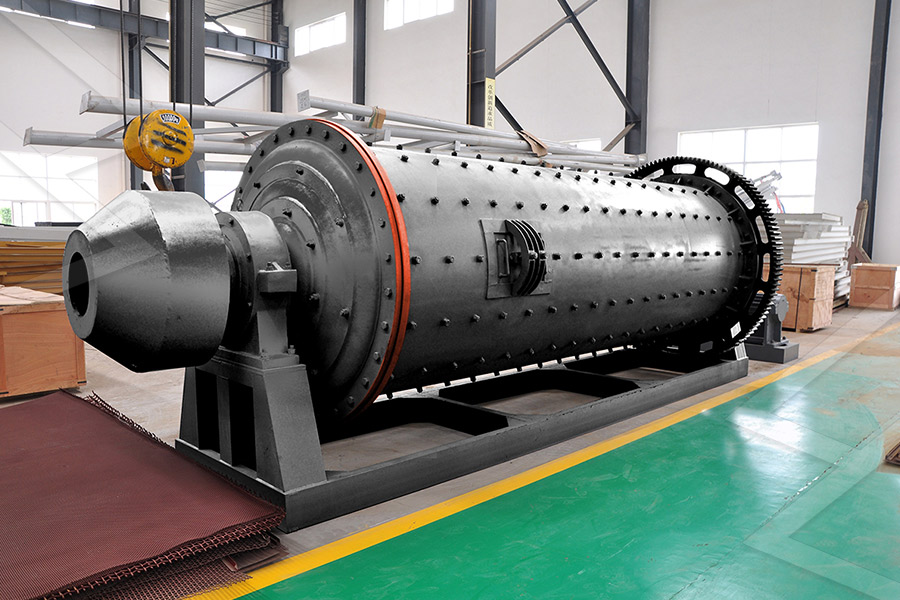

Ball Mills Industry Grinder for Mineral

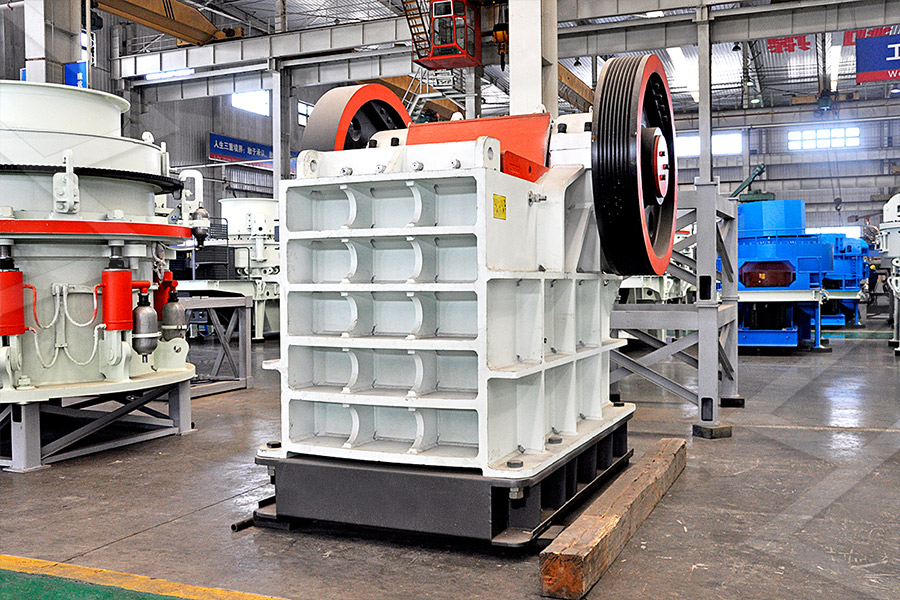

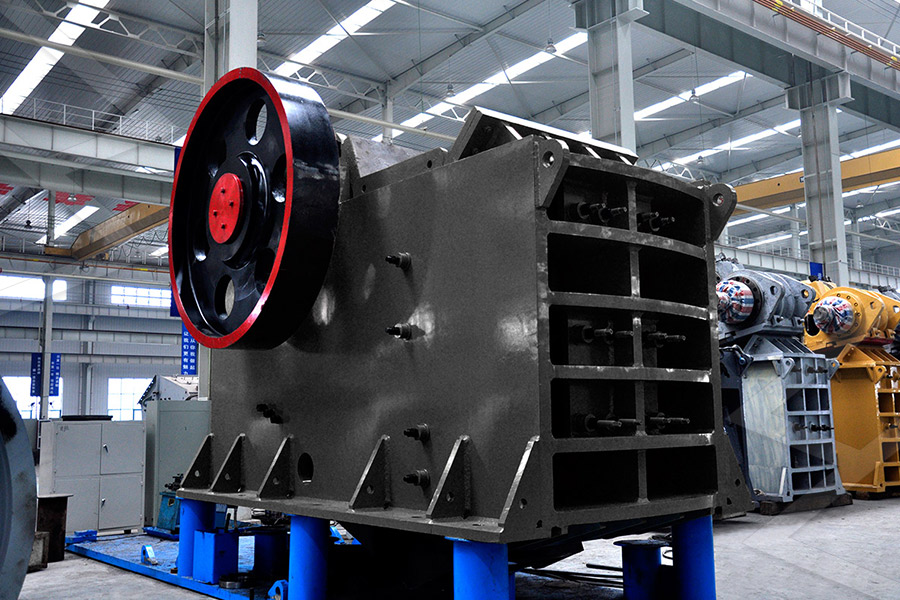

2024年9月9日 — A ball mill, also known as a ball grinding machine, is a wellknown ore grinding machine widely used in mining, construction, and aggregate applicationsJXSC started the ball mill business in 1985, Phrase one: raw material crushing Iron ore blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Crushed iron ore blocks will be sent to the storage hopper by elevator, and then sent to main mill for grinding through feeder Phrase three: classifying Ground material will be classified, coarse powder will fall back to the main mill for ground Iron ore grinding mill Grinding plants for Iron Ore has been focusing on the field of mining ore crushing and grinding machinery for many years Our grinding equipment can grind 100+ kinds of nonmetallic ultrafine powder mills main include HGM series ultrafine grinding mills and CLUM series vertical roller mills They can process hundreds of ore materials, grind hard stone into fine Processing Materials Ultrafine Powder TechnologyYou need IronMills Professional kitchenware that you can trust! FREE SHIPPING, UK MADE, 10 YEAR WARRANTY Argentina GBP £ IronMills Grinders will Amaze Your Senses Our luxury castiron salt and pepper mills are a treat for all your senses Each mill is carefully cast and finished IronMills Quality Cast Iron Salt Pepper Mills UK Made

.jpg)

Metallurgists Mineral Processing Engineers 911Metallurgist

911 Metallurgist can enter the scene and see what you have become blind to We can fix issues in ways you never thought possible Our fresh eyes will open new opportunities for your plant Each mineral processing plant has varied ore types, mining equipment, (crusher, ball mill, flotation, tailings), and management (operating) philosophyThe evaluation and Ball mill is the key equipment for grinding materials those grinding mills are widely used in the mining process, and it has a wide range of usage in grinding mineral or material into fine powder, such as gold, iron,zinc ore, copper, etc JXSC Mining produce reliable effective ball mill for long life and minimum maintenance, incorporate many argentina iron ore ball mill MC WorldINCFor the large volumes of iron ore you produce every day, you need proven and reliable equipment to sustain or increase your production level and avoid unplanned stops Automation, digitalization and use of the latest technology in everything from bulk materials handling stockyard machines to crushers, screens and samplers give you the highest Reliable equipment for iron ore mines 2019年5月7日 — Tips for grinding aluminum practicalmachinist Mar 21, 2007 It's definitely better to mill aluminum to size if you can do it, but we are having problems with parts that are large and thin enough to be next to impossible to mill flat The customer is asking for flat and parallel 0005 so I have been float grinding them 3 times (twice on one Alum grinding mill in Argentina stonepulverizer

.jpg)

Processing of Magnetite Iron Ores–Comparing Grinding Options

2009年1月1日 — Also, equipment like ball mill is used at the final stages of grinding Among the comminution and grinding equipment, HPGR is increasingly utilized as tertiary crusher or primary mill because of 2017年3月20日 — An effect of a grinding method, that is ball mill and high pressure grinding rolls (HPGR), on the particle size, specific surface area and particle shape of an iron ore concentrate was studiedPhysicochemical Problems of Mineral Processing 5 天之前 — Finding suppliers of mining crushers, breakers and grinding mills Crushers, breakers and grinding mills come in several different types Mining Technology has listed some of the leading suppliers of processing equipment in the mining drills and breakers market, based on its intel, insights and decades of experience in the sector The list Mining Crushers, Breakers Grinding Mills for the Mining 2017年11月1日 — An iron ore mill relies on the grinding and impact of grinding balls to complete iron ore crushing The operating process of an iron ore mill is as follows: first, the ores are poured into the mill, and both the ores and the grinding balls are lifted by the lifting bar arranged on the wall of the cylinder body to a certain height, after which Friction and wear of liner and grinding ball in iron ore ball mill

Research of iron ore grinding in a verticalrollermill

2024年9月6日 — One contribution to minimise the increase is to use more efficient comminution equipment Verticalrollermills (VRM) are an energyefficient alternative to conventional grinding technology One reason is the dry inbed grinding principle Results of extensive test works with two types of magnetite iron ores in a Loesche VRM are 2021年11月1日 — The pilotscale mill consisted of a 416 cm diameter cylindrical steel shell that was fitted with eight 130 mm width and 60 mm height rectangular lifters (Fig 2)The mill was fitted with two exchangeable discharge endplates, allowing for either overflow or grate discharge operation (Fig 2)The dry ore entered the mill through a variable speed Mechanistic modeling and simulation of grinding iron ore Argentina GBP £ IronMills Grinders will Amaze Your Senses Our luxury cast iron salt and pepper mills are a treat for all your senses Each mill is carefully cast and finished The comforting heft of the cast iron will remind you of its quality with every use Our remarkable colour selection will certainly match your personal style The Stainless Mill IronMillsOur luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free US Shipping We offer FREE standard shipping on all orders above £50 to a UK address (5 days)The Coral Mill CastIron Salt Pepper Grinders IronMills

.jpg)

Experimental investigation of the impact breakage

2023年4月1日 — Experimental investigation of the impact breakage characteristics between grinding media and iron ore particle in ball mills Author links open overlay panel Zixin Yin a b, Nan It provides an effective prediction method for predicting the broken mass distribution of iron ore particles in the ball mill Download : Download highres image Our luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free Shipping to Australia We offer FREE standard shipping on all orders above £50 to a UK address (5 days)The Coral Mill CastIron Salt Pepper Grinders IronMillsFine crushing and screening mobile station High Gradient Magnetic Separator HPT Cone Crusherargentina iron mine grinder mill tehotenskekurzy2013年8月1日 — Likewise, Hebbar (2011) has studied the grinding wear behaviour of austempered ductile iron as media material in the comminution of Kudremukh haematite iron ore in a ball mill The grinding experiments were conducted under different pH conditions, ie pH = 70 and pH = 85, while keeping other parameters fixed, at a mill speed of 74 Consumption of steel grinding media in mills – A review

The Coral Mill CastIron Salt Pepper Grinders

Our luxury castiron salt and pepper mills use a crank handle design for effortless grinding featuring coral red Free UK Shipping We offer FREE standard shipping on all orders above £50 to a UK address (5 days)2021年3月15日 — Rodrigues et al (2021) showed that autogenous or semiautogenous grinding (AG or SAG) would lead to significant simplifications to Brazilian industrial iron ore paring strategies for grinding itabirite iron ores in 2021年1月14日 — energy required which in this case was to grind the ore represented by the samples, from a feed size F80 of 152 mm to 80% passing 17 mm, and a simple adjustment procedure in case the SAG product size needed to be adjusted Bond rod and ball mill work indices are readily converted to pinion energy for rod and ball mills but not for SAG parison of Ore Hardness Measurements for 2020年5月15日 — 212 Ore Blend Grinding at HPGR and Ball Mill The ore blend was ground in a pilotscale HPGR (1 m diameter × 032 m width) at a maximum feed rate of 50 t/h The Development of a Novel Grinding Process to Iron Ore Pelletizing through HPGR Milling in Closed Circuit Development of a Novel Grinding Process to Iron Ore

.jpg)

argentina iron ore grinding mill Sabo Mining Machinery

2023年9月3日 — Development of a Novel Grinding Process to Iron Ore WebMar 28, 2020 212 Ore Blend Grinding at HPGR and Ball Mill The ore blend was ground in a pilotscale HPGR (1 m diameter 032 m width) at a maximum feed rate of 50 t/h2020年5月28日 — The feed samples of X, Y, and Z iron ores were ground in the BBM (ball mill refers to a BBM of size 300 mm × 300 mm with smooth liners) to identify the PSD, BWI, and RT of each ore Grinding experiments were conducted according to Bond’s standard test procedure []For each iron ore sample, the RT taken to produce 250% circulating Investigation on Iron Ore Grinding based on Particle Size Distribution AS a leading global manufacturer of crushing and milling equipment, we offer advanced, rational solutions for any sizereduction requirements, including quarry, aggregate, grinding production and complete stone crushing plantore used in siderca mill argentina from where agroequi2022年3月19日 — An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particles The effects oGrinding iron ore concentrate by using HPGR and ball mills

.jpg)

The six main steps of iron ore processing Multotec

Grinding The primary grinding mill grinds the material before it undergoes spiral gravity separation Efficient grinding means that there will be minimal recirculation material from a cyclone cluster or screening after milling, which decreases the kWhr per ton ground When the material exits the mill, the iron ore is classified using 2024年4月26日 — Grinding Mills: Grinding mills, such as ball mills and rod mills, are commonly used for grinding iron ore These mills contain grinding media (steel balls or rods) that tumble and impact the ore, causing it to break into smaller particles The choice of grinding mill depends on factors such as the desired product size, capacity requirements Iron Ore Processing: From Extraction to Manufacturing2020年10月18日 — An iron ore concentrate sample was ground separately in a pilotscale HPGR mill in multiple passes and a dry opencircuit ball mill to increase the specific surface area of particlesThe effects of iron ore concentrate grinding methods (HPGR DOI: 101016/JPOWTEC202107030 Corpus ID: ; Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills @article{Carvalho2021MechanisticMA, title={Mechanistic modeling and simulation of grinding iron ore pellet feed in pilot and industrialscale ball mills}, author={Rodrigo M de Mechanistic modeling and simulation of grinding iron ore

.jpg)

IronMills Quality Cast Iron Salt Pepper Mills UK Made

You need IronMills Professional kitchenware that you can trust! FREE SHIPPING, UK MADE, 10 YEAR WARRANTY Argentina GBP £ IronMills Grinders will Amaze Your Senses Our luxury castiron salt and pepper mills are a treat for all your senses Each mill is carefully cast and finished 2024年1月2日 — Population balance model approach to ball mill optimization in iron ore grinding Patricia M C Faria1,2, Luís Marcelo Tavares2 and Raj K Rajamani3 1 Vale SA, Brazil 2 Department of Population balance model approach to ball mill 2020年3月28日 — Based on batch grinding method and normalization idea, a conical ball mill is used and a quantitative separation method of grinding characteristics of multicomponent complex ore is proposedDevelopment of a Novel Grinding Process to Iron Ore Request PDF On Mar 15, 2015, Mathis Reichert and others published Research of iron ore grinding in a verticalrollermill Find, read and cite all the research you need on ResearchGateResearch of iron ore grinding in a verticalrollermill

.jpg)

Research of iron ore grinding in a verticalrollermill

2015年3月15日 — Pilot scale mill LM45 For the grinding tests, a Loesche mill LM45 (table diameter 045 m) is used (Fig 2a) This pilot scale mill is a special development for ore grinding, which is reflected by several features The mill has four rollers, which are able to stress the particle bed with grinding pressures of up to 5000 kN/m 2 Various 2023年10月27日 — The ball mill is a rotating cylindrical vessel with grinding media inside, which is responsible for breaking the ore particles Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the materials used to manufacture them and the A Review of the Grinding Media in Ball Mills for Mineral